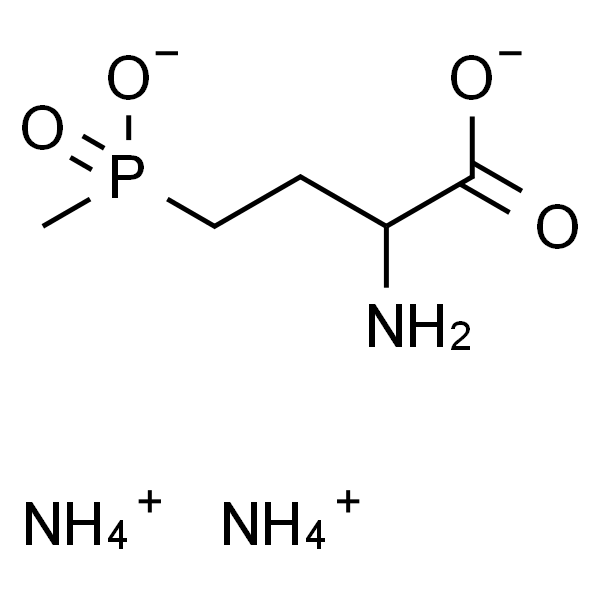

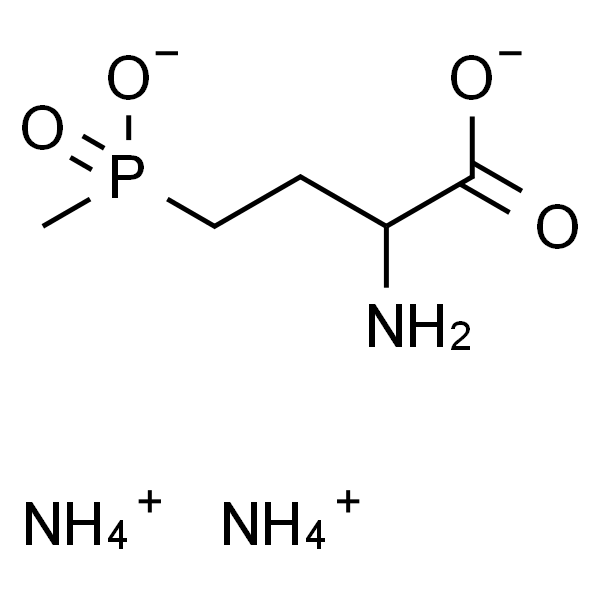

Synthesis of Glufosinate-Ammonium Method 1

Currently, there are three main production processes for glufosinate-ammonium worldwide, with the most challenging one

being the high-temperature decomposition ACA process developed by Bayer BASF.

Bayer (BASF) is the inventor of glufosinate-ammonium, so what does their production process look like? In the first step,

methyl dichlorophosphate (MDP) reacts with isobutanol to produce methylphosphonate ester (MPE). Simultaneously, acrolein,

sodium cyanide, and acetic anhydride react to synthesize 2-acetoxy-3-butene (ACA). ACA and MPE undergo a Michael free radical

addition reaction, resulting in the formation of 3-(acetoxy)-3-(cyanopropyl)-methylphosphonate (ABMP). Subsequently, ABMP

undergoes amination, hydrolysis, and finally yields glyphosate-ammonium.

The glufosinate-ammonium obtained from this process has an estimated cost of 5,800 to 7,200 US dollars per ton, which is relatively

low. The yield is also above 92%, and the reaction process is solvent-free, odorless, and does not emit any residues, making it

environmentally friendly. However, due to the requirement of a temperature above 600 degrees Celsius for the reaction, it

demands high-quality reaction equipment and involves high investment. Additionally, the research on the Michael free radical

addition and MDP processes is not yet mature, making it difficult for other manufacturers to replicate their production methods.

Latest News

Contact Us

Name: Kim Gong

Tel: +86-15150222860 , +86-18015677881

E-mail: [email protected]

Skype: kim.gong

QQ: 326296678

WeChat: +8615150222860

Whatsapp: +8615150222860

Add: No.268, Jingang Road, Zhangjiagang Free Trade Zone, Zhangjiagang City, Jiangsu Province, China

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online